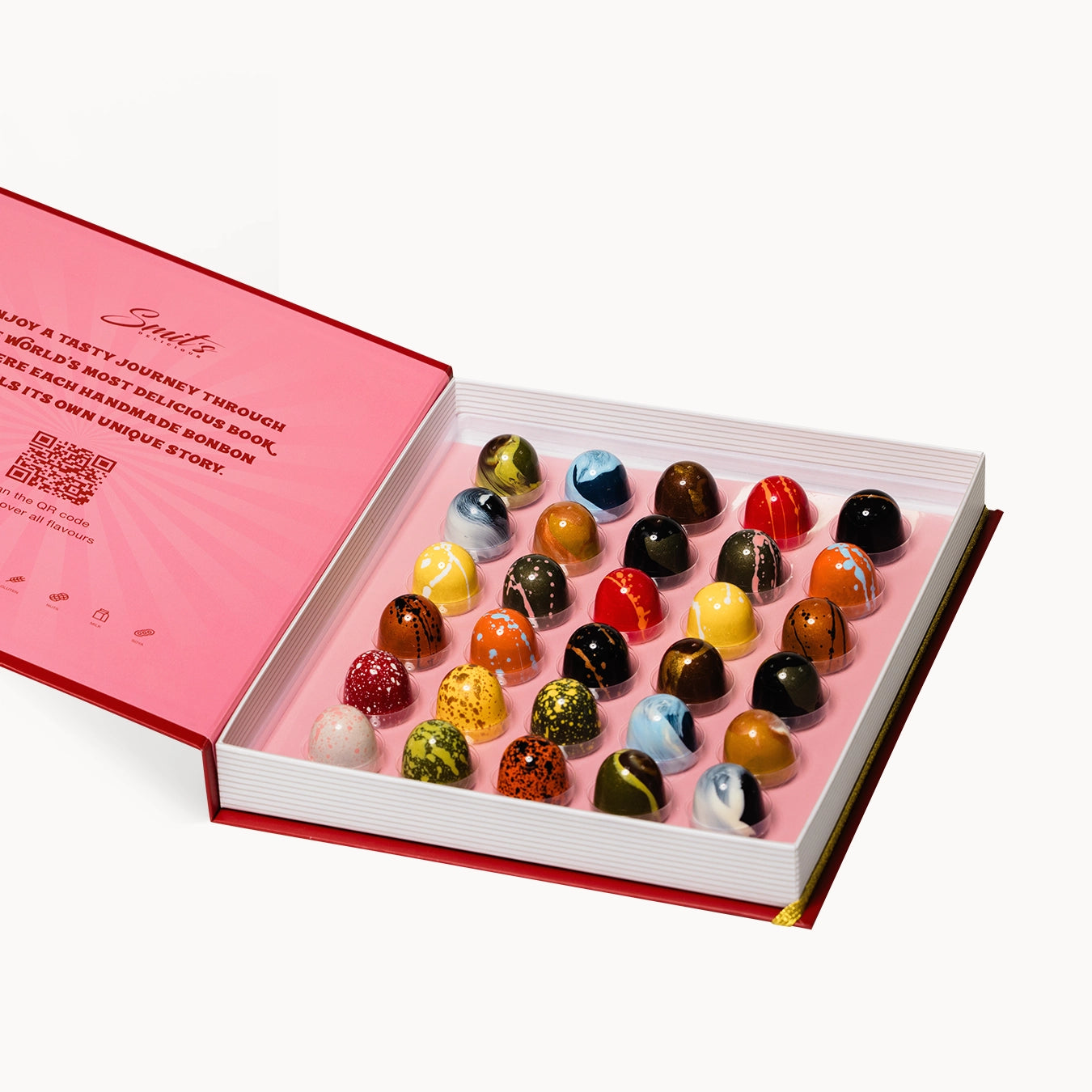

Chocolate is one of the world's most beloved treats, but the process of making it is an art in itself. From harvesting the cacao to shaping the perfect bonbon, every step plays a crucial role in the flavor and quality of the chocolate. In this blog post, we'll take you through the chocolate-making process and explain why we at Bonbonbook choose high-quality Valrhona chocolate.

1. The Origin of Chocolate: Harvesting Cacao

Chocolate begins with the cocoa bean, which comes from the cacao tree (Theobroma cacao). Cocoa is primarily grown in tropical countries such as Ghana, Ivory Coast, and Ecuador. The ripe cocoa pods are handpicked and opened to extract the cocoa beans. These beans are then fermented and dried to develop their flavor.

Learn more about where our chocolate comes from

2. Fermentation: The basis for rich chocolate flavors

After harvesting the cocoa pods, the beans are fermented, a crucial process for developing the flavors we so appreciate in chocolate. Fermentation takes place in wooden or plastic crates and usually lasts between two and seven days. During this period, natural yeasts and bacteria break down the sugars in the beans, resulting in the characteristic flavor development. Fermentation is a delicate phase, where the correct temperature and humidity play a major role. This process enhances the complexity of the cocoa flavor, ultimately contributing to the deep, rich flavors you'll find in the chocolate we use at Bonbonbook.

3. Roasting cocoa beans

After fermentation and drying, the cocoa beans are roasted. This process is crucial, as it determines the final flavor of the chocolate. The beans are roasted at a high temperature to separate the shell from the cacao nibs, the small pieces of the bean that form the base of the chocolate. Roasting extracts the rich aromas and flavors from the beans, giving the cocoa its characteristic aroma and taste.

4. Grinding and making chocolate mass

The roasted cocoa beans are ground into cocoa mass, also called cocoa liquor (although it doesn't contain alcohol!). During this process, heat is generated, causing the cocoa beans to melt. The resulting mass consists of cocoa butter (the fat from the cocoa bean) and cocoa liquor (the solid part).

5. Mixing ingredients

Now comes the magic step: mixing the cocoa mass with other ingredients. Depending on the type of chocolate, sugar, milk powder (for milk chocolate), and sometimes vanilla or other flavorings are added. This mixture is then thoroughly mixed and refined to achieve a smooth, silky texture. This process is called conching.

6. Tempering: The Secret of a Shiny Chocolate

Tempering is a technique in which chocolate is cooled and reheated in a controlled manner to stabilize the crystallization of the cocoa butter. This ensures that the chocolate is glossy, firm, and brittle, and that it retains its long-lasting flavor. Tempering is an art that requires skill, and it's one of the reasons why top chocolatiers like us at Bonbonbook always take their time with this process.

7. Shaping and cooling

The resulting chocolate is then molded into the desired shape: whether bonbons, bars, or other treats. The chocolate is slowly cooled to maintain its texture and be ready for packaging and sale.

Why do we choose Valrhona chocolate?

At Bonbonbook, we use Valrhona chocolate , one of the world's most prestigious chocolate producers. Valrhona is known for its dedication to using the finest cocoa beans and creating unique, refined flavors. Valrhona chocolate is made with respect for tradition and craftsmanship, and we appreciate the rich, complex flavors it offers.

Read more about why we choose Valhrona chocolate

Valrhona collaborates with local cocoa farmers and uses sustainable production methods that contribute to a better future for both the farmers and the environment. By choosing Valrhona, we can offer you the highest quality chocolate, which you'll find in all our handmade bonbons.

At Bonbonbook, we believe the best chocolate starts with the best ingredients, and Valrhona allows us to deliver the highest quality and taste you deserve.